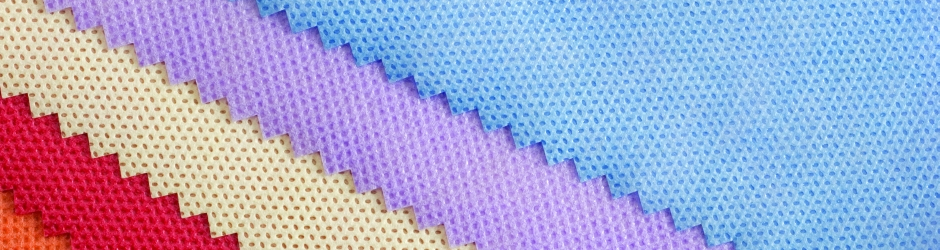

Nonwoven needle felts are the main material of filter bag. Gentuğ needle felts are excellent for gas filtration and dust collection, as well as liquid/solid separation. They are extensively used in blast furnace gas, cement plants, metallurgy, chemical plant, foodstuff, architecture, etc.

Most industrial dust wills blast when they meet the static discharge if its content comes to a certain extent. This brings on the explosion and fire. For example, the dust in flour, chemical and coal industries are of this kind. So in the de-dusting application of this case, the dust should be collected with special dust bags which are anti-static.

Gentuğ absorbed the advanced technologies and developed the anti-static needle felts and cloths. They can meet the special demands of the dust collection of blast furnace gas and coal gas in the cement industry.

Our anti-static products have been authorized.

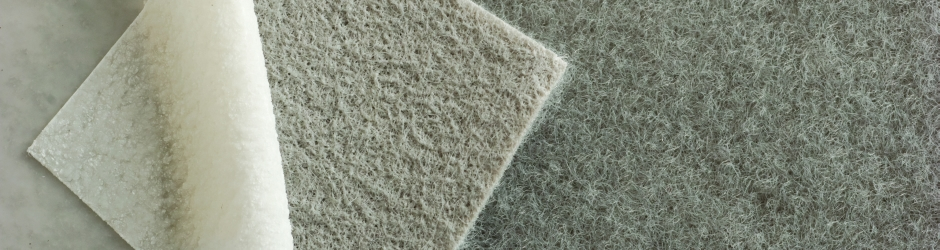

In the filtration process of the filter bag, the dust is very easy to adhere to the bag if the content of moisture and oil in the gas is high. This is helpful to the dust collection, however at the same time makes the clean difficult. Moreover, the dust will jam the finestra of the bag and corrupt the material which increases the flow resistance.

Gentuğ solves the problem by developing a new cloth. This innovative product is hydrophobic & oleophobic.

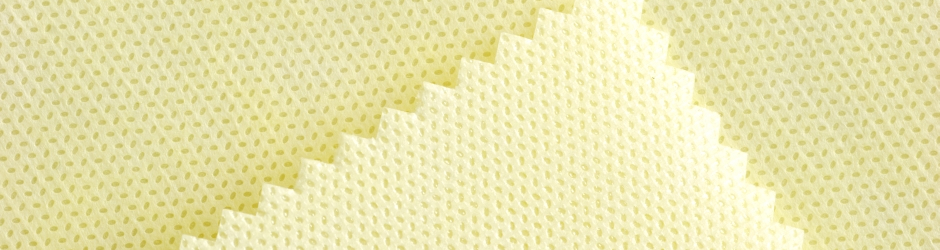

Benefits from the good physical and chemical characteristics of polypropylene, the PP felts are wearable, acid & alkali resistant and have good air permeability. So they are usually used in the strong acid and alkali conditions. Besides the dust collection application, PP needle felts are also used in the liquid filtration processes.

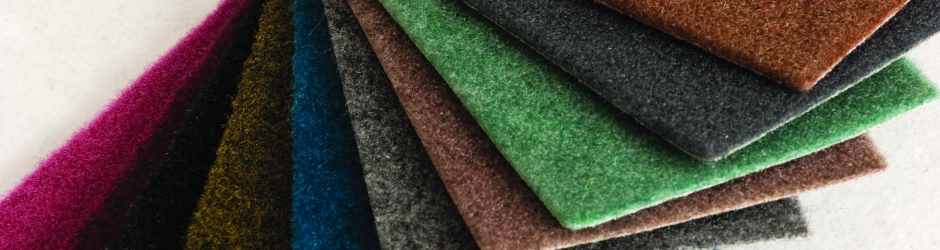

Our hi-temp resistant felt are used in the following applications: Asphalt, ceramic, metal, refuse incinerators, cement & lime, coal, power plants, waste recycling, etc.